उत्पादनाचे वर्णन

1.Streamlined design originated from EU; adopt overall welded and annealing heat treatment technology to eliminate the machine stress, good rigidity and high accuracy, to ensure the prolonged use without deformation

2.Use double screws and dual-servo motor transmission mechanism which can significantly improve the machine reliability and cutting speed

3.Full-digital CNC controls servo motor

4.Gantry structure, use international top-notch brand speed reducer and high precision linear guide rail, balance transmission, high accuracy

5.Overall casting aluminum beam, the first processing was preceded after two times annealing treatment, then VSR (vibratory stress relief) and high precision processing forming.

6.Adopt world-class full-automatic electric proportional valves which can precisely control the cutting assist gas pressure in order to achieve best cutting results.

7.Outside fiber circuit is maintenance-free, and the vulnerable components consumption is very low

8.Professional fiber laser cutting software with drawing layout and acute angle smoothing functions is conductive to realize high-speed punching and marking function.

9.Compact overall layout needs small floor area, especially suits metal processing enterprises in advertising industry..

मुख्य वैशिष्ट्ये

1.Supporting AI, DXF, PLT, Gerber, LXD and other format graphics, accepted international standard G-codes generated by Master Cam, Type3, Wentai and other software.

2.Automatically optimize external DXF files, including: removing the duplicate lines and minimal graphics, automatically distinguishing internal and external modules and sorts etc, and merging connected lines. All the aforementioned functions can be realized by customization or by hand.

3.Supporting common editing and typesetting functions, including zoom, move, mirror, rotate, align, cope and combination etc.

4.Setting the direction of in/out lines and cutting seam compensation, and executing in line inspection

5.Supporting curve segmentation, merging, curve smoothing, text converting curve, parts merging, breaking up etc.

6.Automatic layout function saving time and labor, automatically lace and off-cut

7.Plate can be easily fully covered through a variety of layout ways

8.Flexible and diverse automatic sorting and manual sorting functions that can lock processing sequence of internal graphics through groups

9.Unique processing sequence, simulate interactive mode for viewing processing sequence.

10.One key sets cutting path. more easy and efficient

11.Support segmental punching, progressing punching, grouping pre-punching, and support separately setting laser power, frequency, laser forms, gas type, air pressure, peak current, delay, following heights etc during punching or cutting course

12.Real-time editing frequency and power curve and setting related low-speed starting parameters

13.Powerful material base, all the technology parameters can be stored for second use.

14.Breakpoint memory function, breakpoint forward and backward retrospect, and part graphics processing is accessible

15.Supports any point positioning when machine pause or stopping, and can start from any point

16.One set of software is suitable for cutting tube and plate, and the programming way is identical, supporting intersecting cutting.

17.Supporting height-fixed cutting and outboard following cutting

18.Supporting various cutting ways, precise positioning

19.Strong scalability, up to more than 30 PLC programs, more than 50 programmable process

20.Programmable input/output port, supporting programmable alarm input

21.Support wireless handheld box, Ethernet remote control system

द्रुत तपशील

अनुप्रयोग: लेझर कटिंग

अट: नवीन

लेझरचा प्रकार: फायबर लेझर

लागू साहित्य: धातू

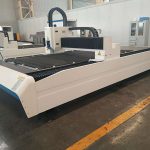

जाडी कापून: 0-30 मिमी

कटिंग क्षेत्र: 3000 मिमी * 1500 मिमी

कटिंग गती: 35 मीटर / मिनिट

सीएनसी किंवा नाहीः होय

कूलिंग मोड: वॉटर कूलिंग

नियंत्रण सॉफ्टवेअर: Cypcut

समर्थित ग्राफिक स्वरूप: एआय, बीएमपी, डीएसटी, डीडब्ल्यूजी, डीएक्सएफ, डीएक्सपी, एलएएस, पीएलटी

Place of Origin: Auhui, China (Mainland)

ब्रांड नाव: ACCURL

प्रमाणपत्र: सीई, आयएसओ, एसजीएस

विक्रीनंतर सेवा प्रदान केलेले: परदेशात सेवा यंत्रणेस उपलब्ध अभियंता

लेझर शक्ती: 500W / 1000W / 2000W / 3000W

कार्यरत क्षेत्र: 1500 मिमीएक्स 3000 मिमी / 2000 मिमीएक्स 4000 मिमी / 2000 मिमी एमएक्स 6000 मिमी

Air system: TaiWan AirTAC

servo motor and driver:Schneider

linear guider: HiWin

Bearings: SKF

Table load weight: 1600 kg

Function: metal cutting

Name: cnc fiber laser steel plate cutting machine